If you make a promise...

You must keep it.

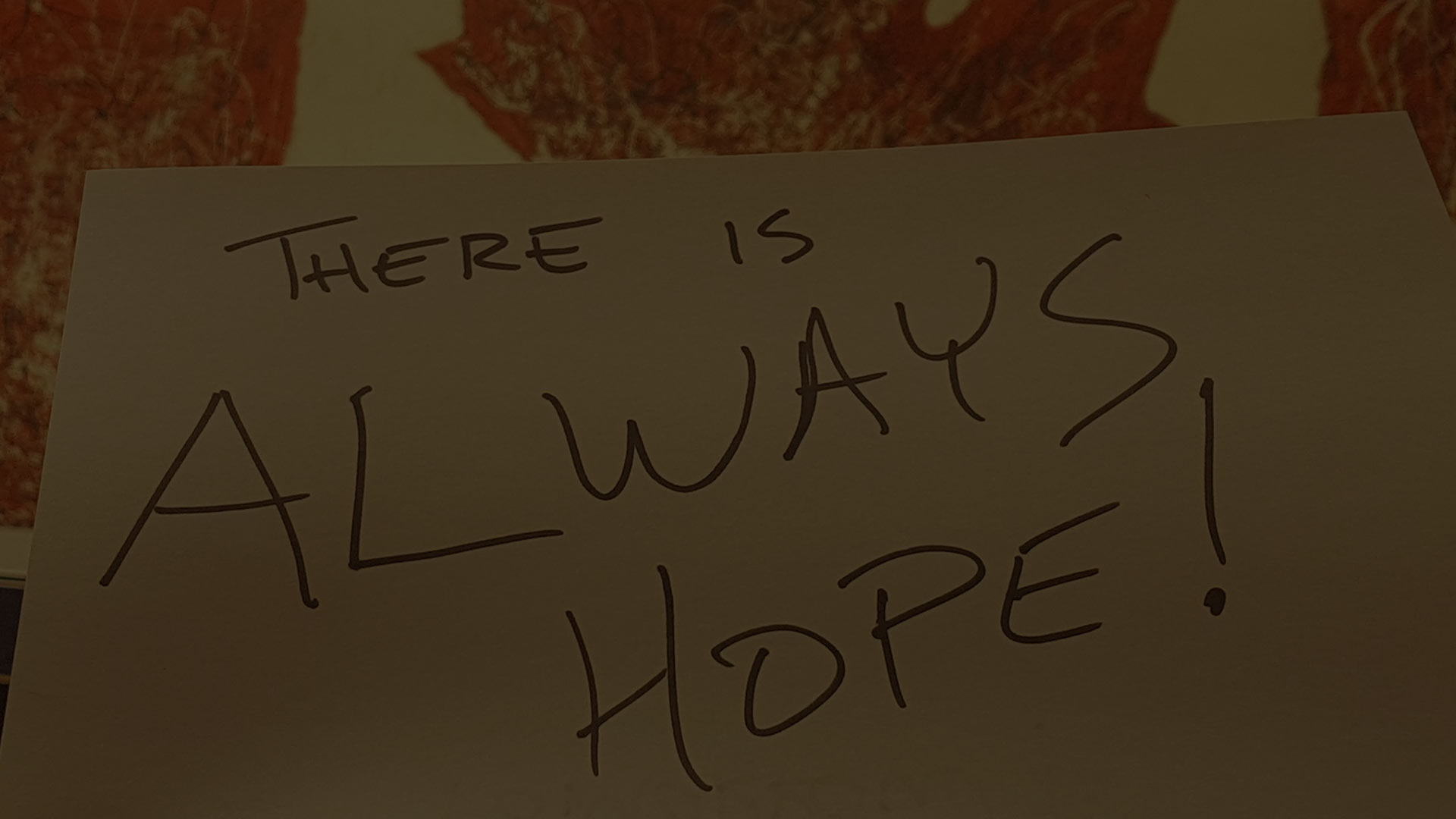

First, I would like to extend a most sincere, personal and professional thank you to anyone who has taken time out of their lives and day to read this. It is my hope that whomever you are, may it serve to inspire you in the pursuit of your dreams.

For those who are unaware of what has happened in our journey, please allow me to explain.

Back in the summer of 2019, we were operating out of a commercial studio in an industrial part of east Edmonton. 4 years was spent renovating and building the space out that would work for our needs. Our landlord, unbeknowst to us, was headed towards a commercial foreclosure, which unlike a residential foreclosure, means that when the bank comes in, they seize everything. With less than 2 weeks notice, we had to find a new space to function out of. After years of tireless work, energy, hope and drive to build the space we wanted, this unforeseen event, really screwed up our ability to function.

–With about 2 weeks notice, and our landlord going into foreclosure, everything needed to be urgently packed up and moved out of our studio.

-With all moves, one never appreciates just how much stuff, especially when you are running a business.

-You can see the glass enclosure made from patio doors harvested from a large apartment renovation. Everything, absolutely everything had to be urgently packed and moved out.

With very little time, measured in minutes, or so it felt, we had no other choice, but to move our operations into the unheated garage of the sister of our leader, Joseph Green. That meant that the garage and its contents needed to be moved out, which required a new shed to be built prior to moving in all of our tooling, gear and inventory. So, a shed was built to house the displaced items from the garage and we commenced the move.

–Thanks to my big sister and her husband and family, they let me move everything into their garage. However, there was so much stuff that a young family with 3 kids has and so, all this needed to be moved out. However, they had no where to put it…so I had to build a shed to house it.

-Now that the shed was built and all the contents from the garage were moved in, I had to begin moving the studio contents into the garage.

-With floorspace area at a premium, I had to mount a 600lb CNC mill to the wall in order to use it. Moving this myself was really painful.

After this extreme event occurred, and all of our tooling was extracted, moving from a space with approximately 900ft2, into a space half the size, we still retained our inherent optimism for our project to honour the Royal Canadian Air Force by completing our vision of producing 100 coins to celebrate 100 years of the formation of the RCAF, culminating in 2024. Then, as we were contending with the extreme chaos a move yields, and after we began publishing pictures of our first Gold Issue dedicated to the Avro Arrow, the only 2.01 Troy Oz Gold Coins ever minted, with select platinum plate, serialised edge markings and full colour printing, our sub-contractor informed us, that they were no longer going to provide us with the coins we could sell, and thereby, severing our lifeline. It was at this point, we had another collector interested in purchasing a coin. There are no words with enough gravity and meaning to convey just how rough, difficult and hard of a pill that was to swallow. We came to the understanding that calls were made, and given how our work when we started, literally set the global standard of excellence in minting, its easy to appreciate that we may have been threatening to our competition.

-Golden Arrow RL-201. The first 2.01 Troy Oz. Find Gold coin ever minted. Once we started posting pictures of our first Gold issue, that’s when the rug was pulled out from under us.

-This chapter felt very much like we were wandering the cold, desolate and isolated landscape of an impossible dream.

-Here is a photo of the garage after years of work, building a floor, walls, bedroom, a mount for the piston which is approximately 1000lbs, which fell a number of times…

So there we were, in a small garage, with our dreams in tatters, our personal lives in chaos and our means to earn a livelihood and keep our promise and word of honour to the RCAF and the Canadian Forces as a whole, was severed. There is nothing like the experience of waking up inside a garage, your life in complete chaos, then having your dreams ripped from you and all the potential that comes with it.

Friends abandon you, family mocks and ridicules you and your character is simply “Tolerated”. Given the immense and unforeseen hardships, we still had the packaging for the Golden Arrow to complete. When we started this and of course we conveyed this to our truly, truly outstanding and utterly amazing collectors, we told them that the packaging has no ETA, it gets done when it gets done, we will move as fast as humanly possible, but it has to be perfect, otherwise we won’t ship. Given how our packaging has been plagiarised in the past, we took the position where we would not post any pictures telegraphing what our packaging would look like, how it would function etc. As we worked on that, while we also searched for a suitable replacement subcontracting mint we could work with, we realised just how tiny of a community this industry is. We spoke with a number of prospects and realised that for one reason or another, they were just not up to the task, be it metal purity, scheduling or otherwise, we found ourselves in a very difficult position. It was at this point, our leader realised that we didn’t have any other choice, but to literally build a mint from scratch. Now please keep something in mind. Our leader, Joseph Green is a designer, and would have been absolutely happy to have developed a relationship with other mints, completed the collection and most likely at the end of the 100 collection, moved on. However, in light of having to make the decision to take on the truly monumental task of building a mint from scratch, has changed that. As he pushed forward, blowing router after router in the pursuit of the packaging for the Golden Arrow, he was offered another small loan in order to begin the process of building our first press. We would like to express our deepest heart felt gratitude to the family of the late Major General Lionel Bourgeois for assisting with this loan which allowed us to build the press and purchase more tools for the packaging. As our gesture of thanks, we dedicated this press to his memory.

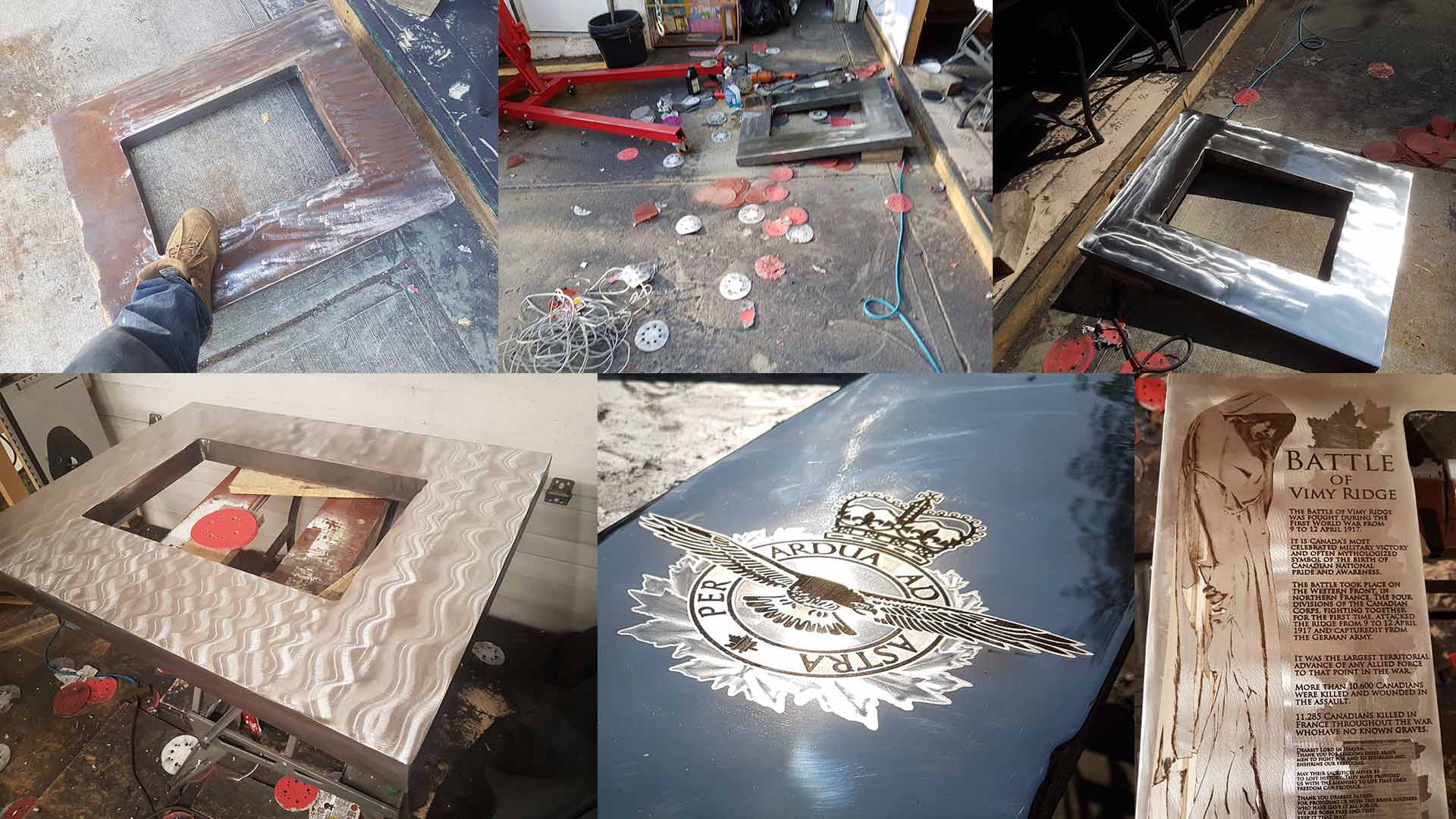

-It took about 3 months to source the steel plate, get it cut, then the protective scale on the steel was ground off, then polished to a mirror finish. If we were expected to produce world class coins, then the press must look the part. Once it was finished, we then laser engraved the first side dedicated to the RCAF, then the other side dedicated to those we lost at Vimy Ridge. During this point, our laser failed and it took a couple of months for a replacement to be shipped.

-It took about 3 months to source the steel plate, get it cut, then the protective scale on the steel was ground off, then polished to a mirror finish. If we were expected to produce world class coins, then the press must look the part. Once it was finished, we then laser engraved the first side dedicated to the RCAF, then the other side dedicated to those we lost at Vimy Ridge. During this point, our laser failed and it took a couple of months for a replacement to be shipped.

-Here is another example of made in China inferior workmanship. This is the Rigid hybrid table saw. We purchased one, the motor failed, we thought it may be a faulty unit, so we replaced it with a second identical unit, and the same thing happened. Never again. We ended up using a saw manufactured in the 1950s because its superior to anything made in China. We had to rip apart our maple hardwood table in order to remove it. Ugh…never again.

-Here my amazing cousin Darren drove into the city from his farm with his skid steer to lift out my press to take it to an oilfield repair shop in Nisku. They fixed it right, welded it correctly and now the press is perfect. It cost more to repair it than the purchase price.

When Joseph Green originally started with the precedent setting Silver Arrow coin, he drained all of his savings, maxed out his credit cards and personal lines of credit in order to produce the first batch of coins. Now, after a successful run of selling our coins, established a track record, that attracted some small amount of investors which was not enough to buy a complete minting system, but enough for us to begin this journey. Now keep in mind, the minting world is replete with trade secrecy, no one divulges anything and no one wants to help, even finding someone who can guide you is an exercise of extreme frustration, resulting in plenty of failed attempts. When the decision was made, we knew we needed a coin press. We had no idea what the terminology is or was, or even how to begin. We just knew we needed a hydraulic press. So with the small backing we had, we purchased a 400T hydraulic piston from China, purchased some 2″ thick mild steel plate locally, had it cut to fit the square flange on the piston and thus began our journey. We then laser engraved it with all the current squadron crests of the RCAF, and all the squadrons of the Air Cadets, the laser failed which incurred a delay of 2 months. Then when the time came to hook up and test the hydraulic piston, the piston leaked and given the amount of work invested into it, if the leak was not sealed, we were prepared to grind off all the engravings as we would not have tolerated a leaky press with the markings of the RCAF and Vimy Ridge. No way, no how. In order to fix it, they sent us a new one which did not fit, it was jammed in, so we had to use our engine hoist, mount it horizontal and use a 6 foot long steel square tube a large wrench to unbind it, and all to lathe of 0.1mm. Luckily we were able to accomplish this. Then after we tested it, everything seemed to be functioning okay, but one day, as we ran another test, the square flange the steel piston was screwed into then welded onto, bent and started to rip off its mount. The company in China used faulty steel that was not adequate to the task. Over the course of this journey, with all the printers, laser engravers, pistons and more we purchased from China, in almost every single case, every single item we purchased failed resulting in the need to conduct expensive repairs, incurring time delays which were beyond unreasonable, months of time was lost trying to repair items that should not have failed and the level of frustration and hardship was off the charts.

-“Whatever it takes…whatever it takes…” There is nothing as humbling and humiliating as living in an unheated garage, appearing like a madman artist to those who have no idea, but when you make a promise to Canada and those who serve, you keep that word of honour as they do with you.

So between pivoting between getting the press issue addressed and operational, trying to figure out the basics like a coin collar, the steel donut which contains the metal while under compression, Green would also be working on other aspects, like the laser. When the laser was purchased, the sales lady had absolutely no clue as to how to operate it, it came with no settings, nor any manual, just some basic, unprofessional videos taken from a cell phone which was supposed to teach how to use it. When the laser was awaiting repairs, Green would pivot over to the CNC mill which itself was another made in China tool with its own set of major problems. So much so, he gave it the name “Pai Mai”, the Kung-Fu master featured in the film Kill Bill.

-Pai-Mai, the CNC of pure misery, our brand new UV wall printer failed on day one and a failed attempt at milling 6061 aluminium for our packaging.

Its difficult to convey just how many elements have gone into building a mint from scratch. Over the course of this journey, we have only had the opportunity to speak with a single individual who works in this industry to be able to ask questions to technical problems. This person works in the manufacturing of tooling for the minting industry and even then, they refused to sell us a coin press insert for our press citing that it was not professionally made. No matter what we did, it was clear, the industry would not welcome us, help us, support us, our vision, our dream and in effect the little guy. Green credits the work he accomplished years earlier of being able to arrange a flag of the Third Battalion Princess Patricia’s Canadian Light Infantry and the lessons learned from that experience which enabled him to keep driving forward against all obstacles.

-Here is the studio in the garage in a clean state which took an incredibly long time to get to.

–Here is an effort to build a new and larger CNC mill out of scrap steel and components from our old CNC. We dismantled the old one because of a critical flaw in the bearing systems and so we attempted to integrate into our primary work table a fully operational CNC mill, however the top gantry was not perfectly square and so we eventually dismantled it. But all the control systems worked and we learned so much from this failure.

-Here is another failure in casting the crest in pewter, but we had a glimmer of hope with the maple leaf and how it will appear with a stunning red powder coat.

There can be no way anyone can appreciate the immense hardship, struggle and pain that this chapter has forced Green to endure. In July of 2022, Green exhausted his resources, in debt, lines of credit maxed, credit cards maxed and literally scrounging for bottles to get enough to buy a pack of smokes, when he had a long discussion with himself and realised that he simply could not continue. Every dollar acquired went into this effort and keeping him alive while in the pursuit. With the immense pressure of debtors and zero income, Green made the call on 31 July and began to accept that he would have to suspend, potentially indefinitely all of his work and head to the oil patch where he has worked previously as a trucker and began to mentally prepare himself for it. It was then his friend and colleague, a lovely lady named Vicky called him up and said she deposited $1000 into his account from some sales and that gave him life. It was a remarkable moment as that was the anniversary of his mothers death and on August 4th, the birthday of his late mother, she deposited a loan of $25k into Beaverworks in order to begin purchasing more tooling and said “There ya go Laddy!” From there, the UV wall printer was purchased, along with other tooling to keep going. For that to happen on those particular days was indeed very heart warming.

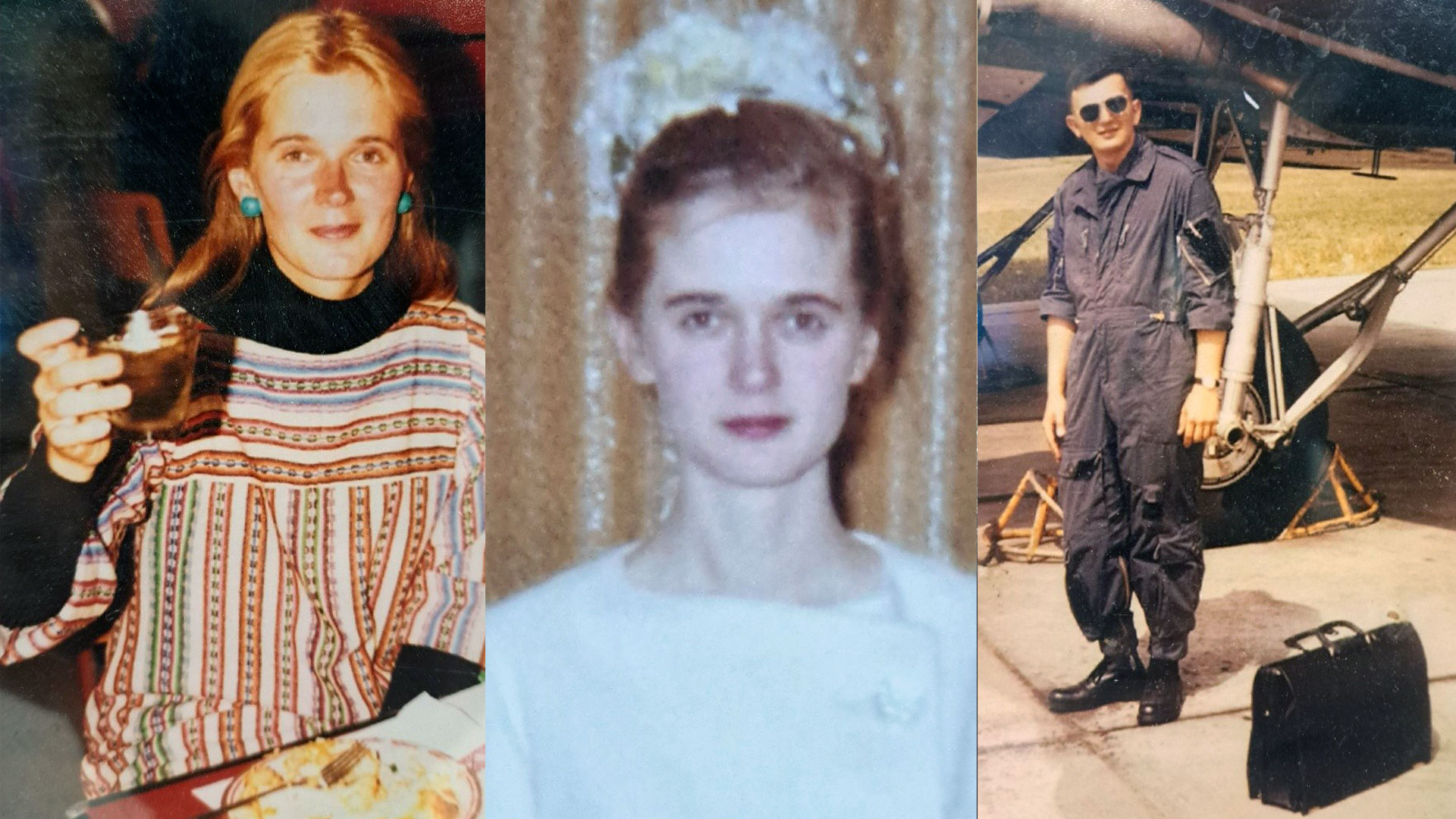

-Just when you think things could not get any more difficult and hard, a couple days after the birthday of Green, his father passed away unexpectedly and he was the one who found him. Green’s father, Joseph M. Green P.Eng, M.Eng E.E. and retired RCAF was an instrumental part of this dream as not only was he exceptionally supportive, he was the one who took care of the accounting. He will be sorely missed for the outstanding support he provided. Without him, we would not be here. Thanks Dad.

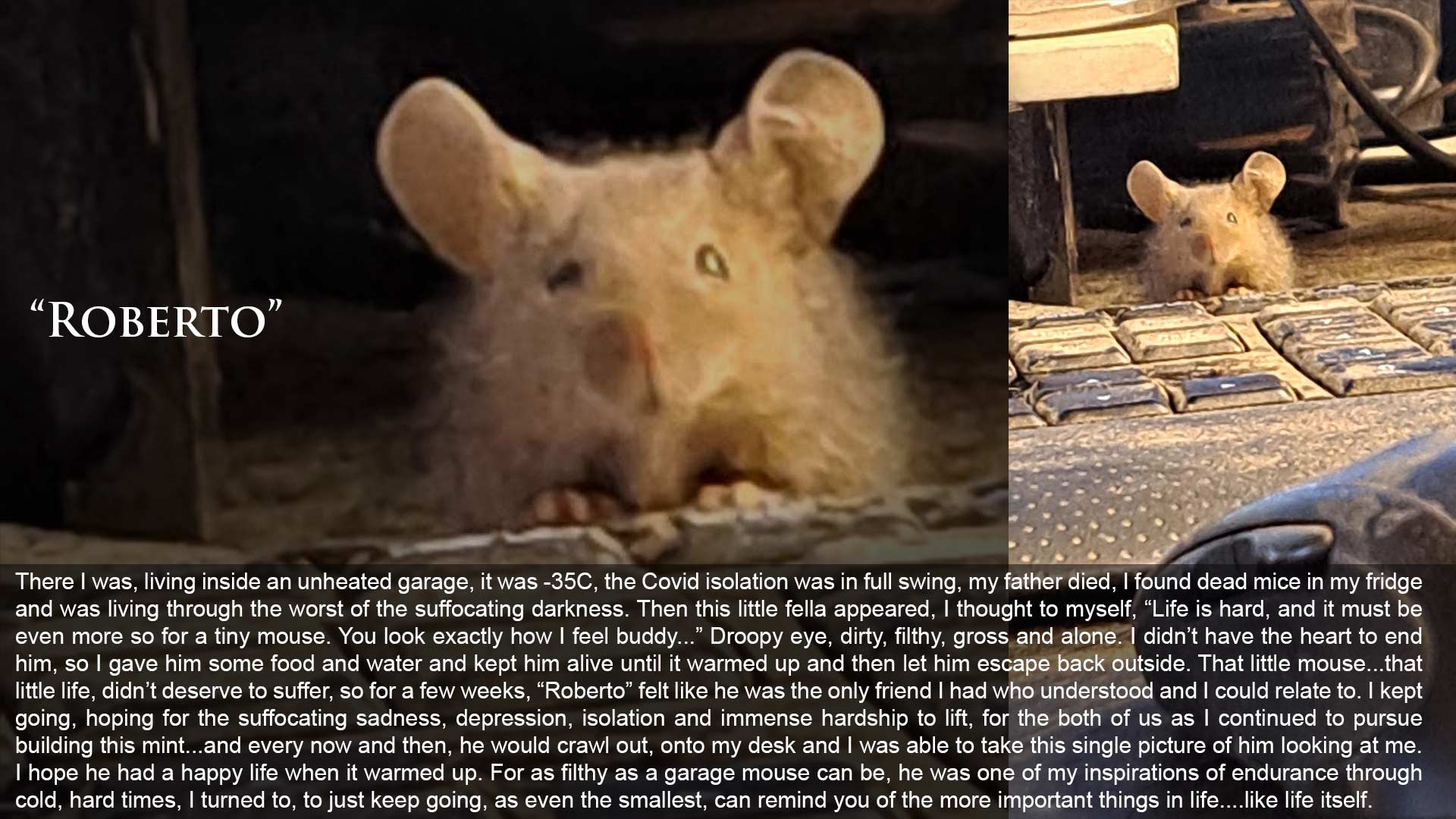

As time went on and Green kept going forward, Vicky agreed to provide another loan so we could stop trying to make what we have worked and just buy a brand new minting system. Everything was proceeding as agreed, then out of the blue, Green’s father passed away and he was the one who found him. Given how Green’s father was the accounting guru and was helping the Legion with their accounting to which Vicky was a member of, when he passed away, it served to disrupt and delay that potential loan. The darkest moments of this journey was felt in the cold winter of November, in an unheated garage, after Green’s father passed away. In the following days, weeks and months that followed, he kept pressing forward for what he could, Vicky went understandably silent without the guidance of his father to assure her and once again, Green felt the vacuum of no funds to keep going. It was during this chapter where he had a life changing moment which solidified his faith, which in turn, kept him driving forward. It is a truly strange thing to know that the money will arrive, when you absolutely need it, you absolutely trust it, you keep going and when the funds are needed, they appear. This project now became the sole mission for Green. With all of his personal furniture given away to family to make room to accommodate tooling, especially in a tiny space, his sole sanctuary is his bed, with literally years invested, massive debts assumed in order to push forward with learning and teaching himself how to mint, embroider, properly print, cast metal and more, out of the blue, Vicky came to the rescue and called him up and apologised for the delay and said that she was ready to commence with the loan. There is something truly bizarre about having to borrow bus fare in order to go and pick up a cheque for $130500.00. That was a day Green shall never, ever forget as it was her which enabled him to bypass all the hardships and turmoil of having to endure having to make due with tools that were not properly made for minting and provide him with the opportunity to purchase proper and calibrated tooling.

-The most amazing supporter and partner one could ever ask for. Vicky Torrie was the wonderful lady who kept people informed of the progress work and also sold our materials at Legion markets. She was an amazing lady and she sadly passed away a day before the first RCAF Silver Maple prototypes were struck. Her passing left an unfillable hole in our lives.